Delhi Rollercoaster Death: A Seatbelt Failure and a Devastating Lesson in Ride Safety SOPs

Published on September 30, 2025 by MoreMeets Team

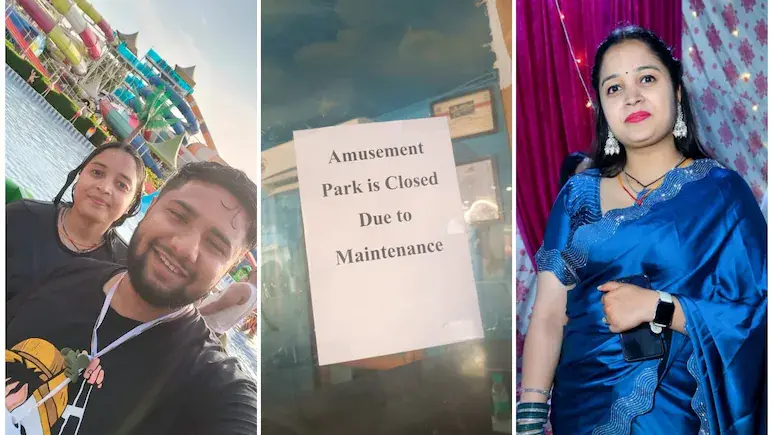

A day of fun at Delhi's Fun N Food Village turned to tragedy when a rider was flung from a rollercoaster, an incident attributed to a seatbelt and fastener failure. This heartbreaking event is a stark reminder that in the world of amusement parks, safety is not a suggestion; it is an absolute, non-negotiable requirement. Incidents like this are rarely 'freak accidents' but are almost always the final, tragic outcome of a chain of procedural failures.

For park operators, engineers, and state regulators, this incident is a critical case study. The difference between a thrilling ride and a fatal one lies in the rigor of a park's daily operations and maintenance culture. The key to preventing these 'never events' is a system of verifiable, checklist-driven Standard Operating Procedures (SOPs).

The 5 Pillars of a World-Class Ride Safety System

A safe ride is not an accident. It is the result of a disciplined, multi-layered system of checks and balances. Here are the five pillars that form the foundation of that system.

Before the first guest ever boards, the ride operator must perform a tactile, physical inspection of every single safety restraint. This includes pulling on every seatbelt, checking every buckle, and verifying that all sensors are functional. This is not a quick glance; it is a logged, signed-off procedure. Our 'Top 15 Seatbelt & Restraint Tests' checklist is a direct implementation of this pillar.

Metal fatigues, bolts loosen, and hydraulic lines wear out. A Preventive Maintenance SOP schedules regular, detailed inspections of all mechanical and structural components based on manufacturer guidelines and ride usage. This moves maintenance from 'fix it when it breaks' to 'fix it before it breaks'.

When a near-miss occurs—a restraint that briefly jams, a sensor that flickers—it must be logged, investigated, and a root cause identified. Ignoring these small warnings is how large accidents happen. A formal protocol ensures that every 'small' problem is treated as a potential catastrophe in waiting.

If a bolt fails, was it an authentic part from the manufacturer or a cheaper, uncertified replacement? A robust SOP requires logging the serial numbers and certificates for all critical spare parts, creating a clear chain of custody and accountability in your supply chain.

A ride operator must be more than a button-pusher. They must be trained and certified on emergency stop procedures, guest screening, and identifying unusual ride noises or vibrations. Regular drills ensure this knowledge is fresh and instantly accessible in a crisis.

The ROI of Safety: Risk vs. Ruin

The cost of implementing a robust SOP program is negligible compared to the cost of a single major incident: multi-crore lawsuits, permanent brand damage, and the immeasurable cost of a human life. As states like Gujarat rightly tighten regulations, having a documented, auditable safety system is not just best practice—it is the price of your license to operate.

Continue Your Journey to Excellence

The concepts in this article are operationalized in the following toolkit:

Theme Park Operations Pack

Premium Pack

Explore The Full Toolkit